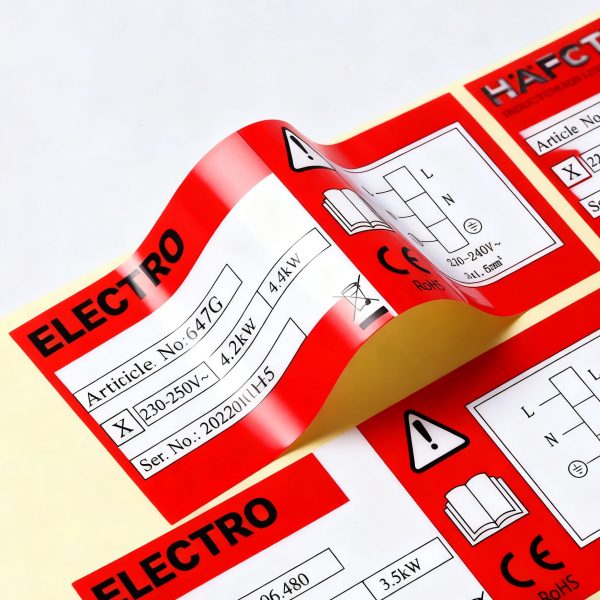

It is a self-adhesive material made with PP synthetic paper as the substrate and oil-based pressure-sensitive adhesive. Its core features are long-lasting adhesion and strong environmental resistance, adapting to various pasting needs in multiple scenarios.

- Excellent Adhesive Performance: The oil-based adhesive has strong initial adhesion, enabling quick fixation after pasting while maintaining long-lasting stickiness. It is not prone to detachment or lifting after long-term bonding and exhibits good compatibility with various surfaces such as plastic, metal, and glass.

- Outstanding Environmental Resistance: Compared with ordinary water-based adhesives, oil-based adhesives offer superior waterproof, oil-resistant, and solvent-resistant properties. In humid, oily, or mild chemical environments, the adhesive layer is less likely to hydrolyze and fail, ensuring the label’s integrity and bonding effect.

- Compatible with Substrate Advantages: Inherits the inherent properties of PP synthetic paper—waterproof, tear-resistant, and dimensionally stable. When combined with oil-based adhesive, the overall friction resistance and anti-aging ability are further enhanced, making it less prone to fading and damage during outdoor use.

- Good Printing and Processing Adaptability: PP synthetic paper has a smooth surface, supporting multiple printing methods, and the adhesive layer does not affect the printing effect. During die-cutting and labeling processes, issues such as glue overflow and knife sticking are rare, resulting in high processing efficiency.

- Wide Applicable Scenarios: Boasts good chemical stability. Some compliant products can be used for packaging labels that do not come into direct contact with food. It is also suitable for industries such as daily chemicals, electronics, and hardware, especially for scenarios requiring long-term bonding or exposure to minor oil stains.

Reviews

There are no reviews yet.