Pearlescent film adhesive stickers are pressure-sensitive labels with a pearlescent luster on the surface. Their core advantage lies in “pearlescent texture + practical durability”, combining decorativeness and scene adaptability.

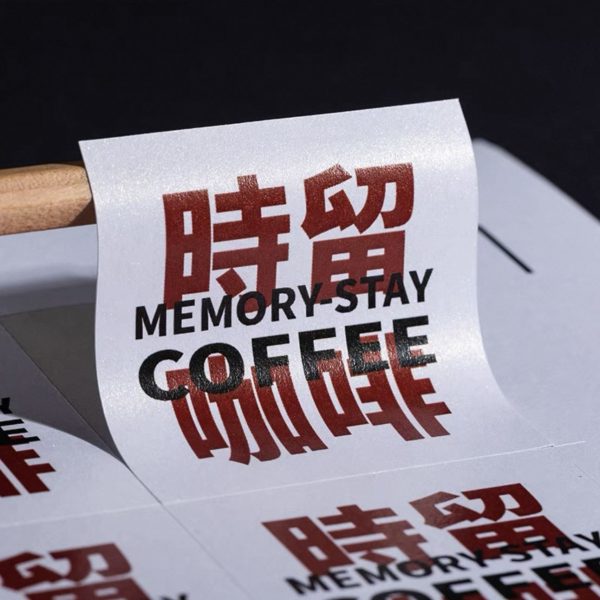

- Unique visual texture: The surface presents a delicate pearlescent luster with a soft reflective effect, inherently conveying a hazy and high-end feel, and has a stronger sense of layering than ordinary solid-color labels. After printing, the color blends naturally with the pearlescent substrate, presenting a warm and full visual effect with prominent decorativeness.

- Solid physical properties: The substrate is mostly PP or PET pearlescent film, which has good flexibility, strong fold resistance and tear resistance, moderate stiffness, and is not prone to wrinkling or deformation. It can maintain the flat shape of the label and is not easily damaged after long-term use.

- Strong environmental resistance: Possesses excellent waterproof, oil-proof, and moisture-resistant properties. In humid environments or when in contact with a small amount of oil, the label will not warp or delaminate, and its pearlescent luster remains unaffected. It also has good scratch resistance and is not easy to fade during short-term outdoor use.

- Wide printing adaptability: Supports various processes such as digital printing, screen printing, letterpress printing, and thermal transfer printing. It has strong ink absorption capacity, can clearly present text, patterns, and complex logos, and the ink layer has strong adhesion and is not easy to fall off.

- Good pasting stability: The adhesive is mostly water-based or oil-based, with strong initial adhesion and long-lasting tackiness. It can firmly adhere to surfaces of various materials such as plastic, glass, metal, paper, and wood, and is suitable for pasting on flat or slightly curved surfaces.

- Widely applicable scenarios: Combining texture and practicality, it is suitable for gift packaging, daily chemical products, food outer box labels, cosmetics bottle stickers, festival decoration labels, and other scenarios. It is especially suitable for label needs that pursue a soft and high-end feel or require differentiated visual effects.

Reviews

There are no reviews yet.