Address

Building C2, Zhanglong Logistics Park

Shiting Sub-district, Xiangcheng District, Zhangzhou City

Fujian Province, P.R. China

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

Building C2, Zhanglong Logistics Park

Shiting Sub-district, Xiangcheng District, Zhangzhou City

Fujian Province, P.R. China

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Self-adhesive labels, widely used in food, cosmetics, electronics, and logistics industries, rely on precise printing processes to achieve both functional performance and aesthetic appeal. Among the various printing technologies, flexographic (flexo), digital, and screen printing stand out as the most mainstream methods, each with unique workflows tailored to different production demands. This article details the complete printing process of self-adhesive labels, focusing on the characteristics, operational steps, and application scenarios of these three core technologies.

1. Pre-Printing Preparation: The Foundation of Quality Labels

Pre-printing preparation is a critical phase that determines the efficiency of subsequent processes and the final quality of labels. It involves material selection, design optimization, and process planning, laying the groundwork for seamless printing operations.

1.1 Material Selection: Matching Performance to Requirements

Self-adhesive label materials consist of three core components: face material (printing surface), adhesive (bonding layer), and release liner (protective base paper). The selection of materials must align with the label’s application environment, such as resistance to moisture, high temperature, or chemicals, as well as printing technology characteristics.

Key principle: High-quality materials are essential—expired or substandard materials may cause printing defects like ink bleeding or poor adhesion, increasing overall production costs despite lower initial procurement prices .

1.2 Design Optimization & Pre-Press Processing

This stage converts customer design requirements into printable files, requiring close collaboration between designers and printing technicians to avoid process conflicts.

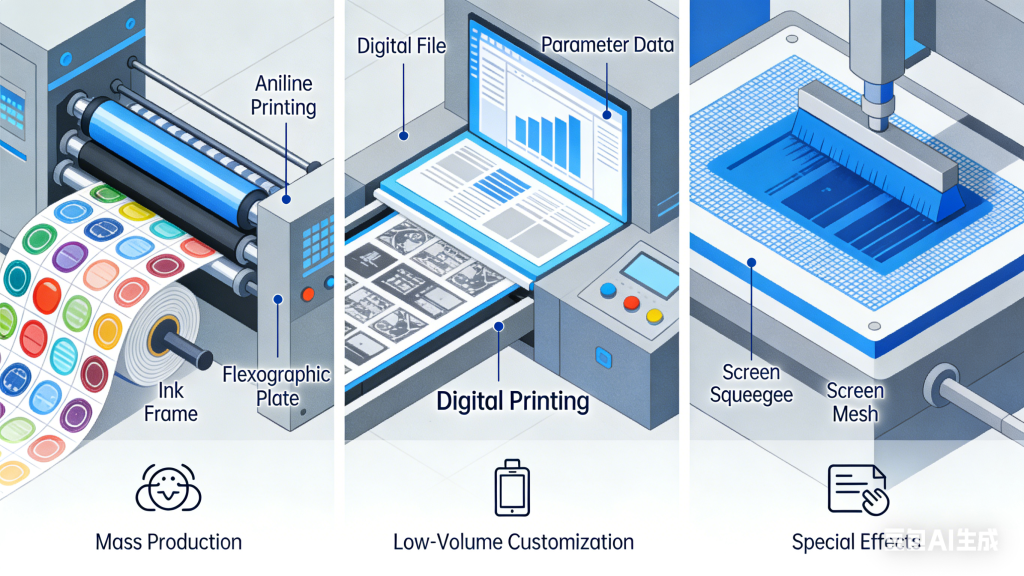

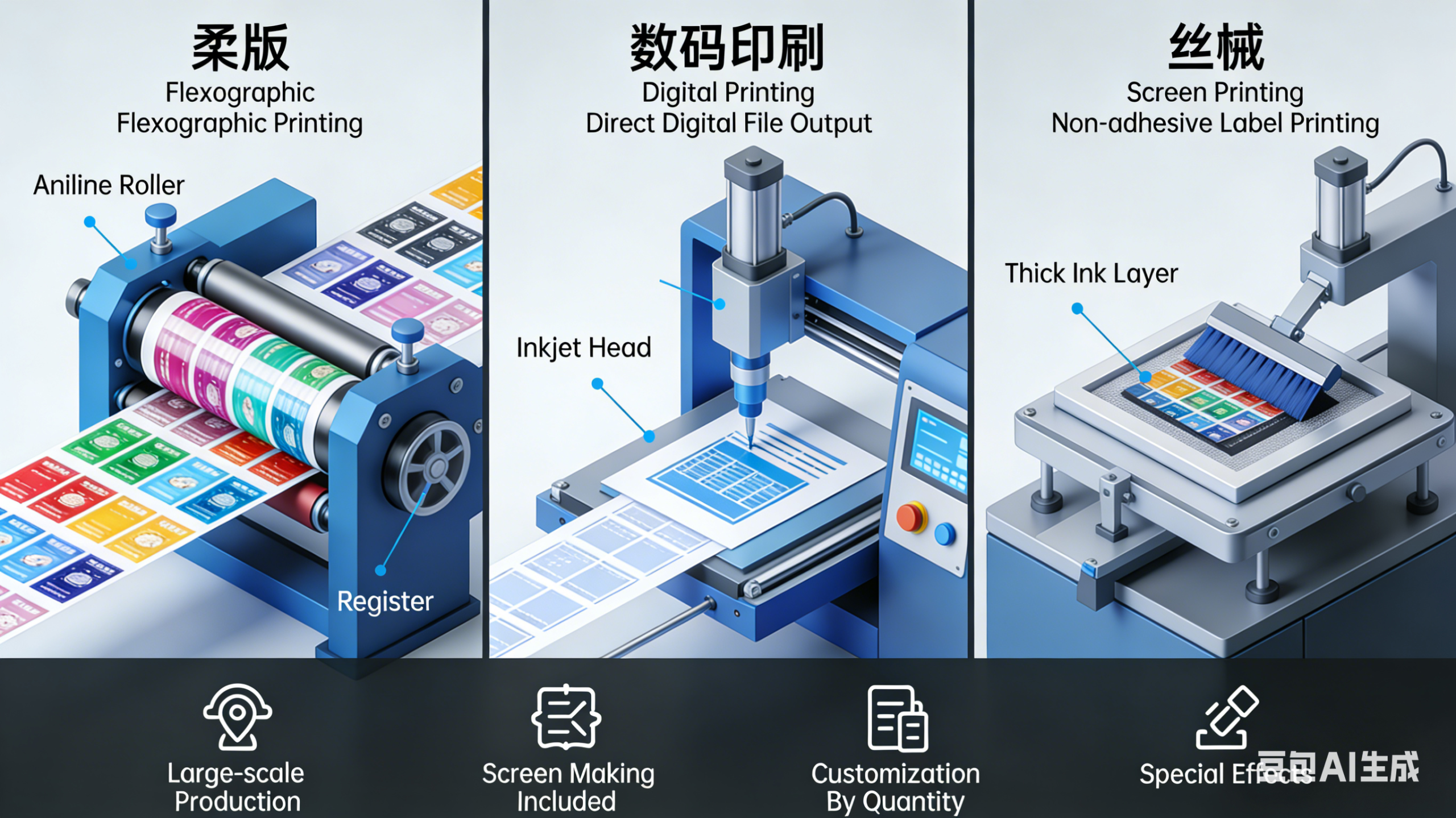

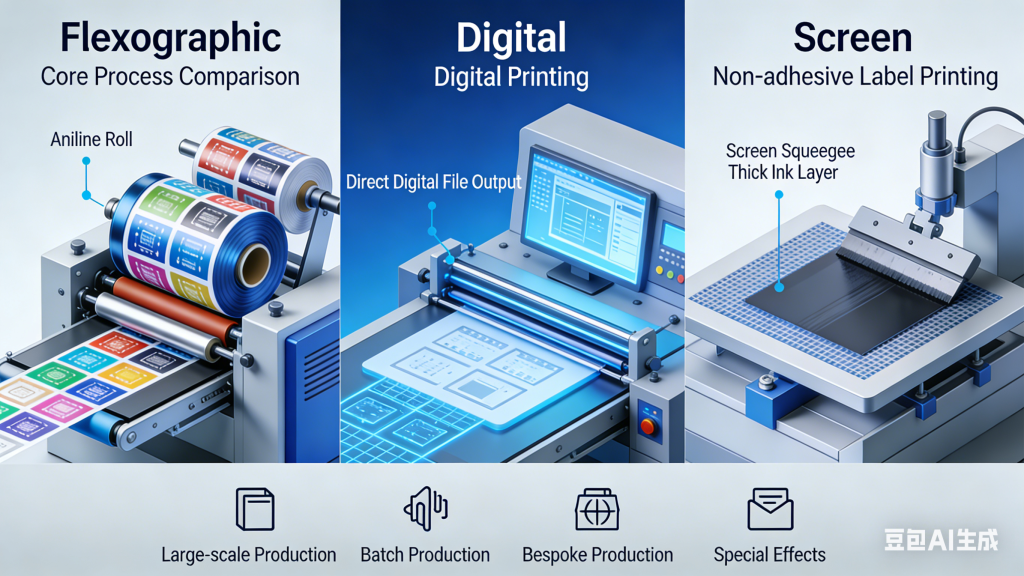

2. Core Printing Processes: Flexo, Digital & Screen Printing

The three printing technologies differ significantly in principle, equipment, and workflow, making them suitable for distinct production scenarios. Below is a detailed breakdown of each process.

2.1 Flexographic Printing: The Mainstream for Mass Production

As the most widely used self-adhesive label printing method—accounting for 40-50% of the European market and over 90% of the U.S. market—flexo printing is a rotary relief printing technology known for high speed, versatility, and cost efficiency . It is particularly suitable for large-batch orders (≥100,000 labels) such as food and beverage packaging.

Ink is transferred from anilox rollers (which control ink volume via micro-holes) to the raised image areas of flexible plates, then directly pressed onto the moving substrate (roll-to-roll feeding). Each color requires a dedicated plate and printing unit, enabling multi-color overprinting .

2.1.3 Advantages & Limitations

Advantages: High printing speed (up to 300m/min), wide substrate adaptability (paper, film, foil), cost-efficient for large batches, and support for eco-friendly inks . Limitations: Time-consuming setup (plate installation, color adjustment) makes small-batch production costly; fine text reproduction is slightly inferior to digital printing .

2.2 Digital Printing: The Leader in Flexibility & Personalization

Digital printing, a plate-free technology that directly transfers digital files to substrates via inkjet or laser, has become the preferred choice for small-batch, personalized labels. It excels in scenarios requiring variable data (e.g., QR codes, serial numbers) and fast turnaround, such as e-commerce, limited-edition cosmetics, and pharmaceutical labels .

Inkjet digital presses eject tiny ink droplets onto the substrate to form images; laser digital presses use electrostatic adsorption to transfer toner, which is then fused to the surface via heat. The entire process is controlled by RIP software, enabling real-time adjustments to designs .

2.2.3 Advantages & Limitations

Advantages: No plate setup (saves 2-3 days of preparation time), low minimum order quantity (even 100 labels are cost-effective), high flexibility for design modifications, and precise variable data printing . Limitations: Higher unit cost for large batches compared to flexo printing; some special films may require pre-coating for better ink adhesion .

2.3 Screen Printing: The Specialist for Special Effects

Screen printing, characterized by thick ink layers and strong three-dimensional effects, is a versatile technology suitable for almost all substrates—including plastic, metal, and glass. It is commonly used for labels requiring special effects like embossing, matte textures, or luminous patterns, such as electronic product logos and luxury wine labels .

A stencil-mounted screen is pressed against the substrate. Ink is scraped across the screen with a squeegee, passing through the porous design areas to form thick, opaque images on the label surface. Each color requires a separate screen, and UV inks are typically used for quick curing .

2.3.3 Advantages & Limitations

Advantages: Thick ink layers (30-100μm) for strong texture, excellent opacity (suitable for covering existing information), and compatibility with special inks (luminous, conductive, tactile) . Limitations: Low printing speed (mostly semi-automatic), limited precision for multi-color overprinting, and high labor costs for small batches .

3. Post-Printing Processing: Shaping the Final Label

Post-printing processing enhances the label’s functionality (e.g., durability, ease of use) and aesthetics. For efficiency, modern label presses integrate most processes inline; complex effects may require offline processing.

3.1 Surface Finishing: Protection & Aesthetics

3.2 Forming Processing: From Roll to Finished Label

For functional labels: Perforation (for easy tearing of coupon labels), embossing (creating 3D textures for blind labels), and die-cutting through release liner (for single-label dispensing) .

4. Quality Control & Packaging: Ensuring Consistency

Quality control runs through the entire process to avoid defective products. Key inspection items include:

Qualified labels are packaged in moisture-proof, pressure-resistant cartons or plastic film, with labels indicating product specifications, batch numbers, and storage conditions to ensure integrity during transportation .

5. Process Selection Guide: Matching Technology to Needs

Choosing the right printing process depends on order quantity, design requirements, and application scenarios. The following table provides a quick reference:

| Criteria | Flexo Printing | Digital Printing | Screen Printing |

| Order Quantity | Large batches (≥10,000) | Small batches (100-10,000) | Small to medium batches |

| Turnaround Time | 3-7 days (setup time) | 1-2 days (no setup) | 2-5 days (screen making) |

| Key Advantages | High speed, cost-efficient | Personalization, variable data | Special effects, thick ink layers |

| Typical Applications | Food/beverage labels, logistics labels | Limited-edition cosmetics, e-commerce labels | Electronic logos, luxury wine labels |

The self-adhesive label printing process is a systematic project integrating material science, printing technology, and post-processing. Flexo printing dominates large-scale production with efficiency and cost advantages; digital printing leads the way in personalized and short-run orders with flexibility; screen printing excels in special effects to meet high-end aesthetic needs. By understanding the characteristics of each process and matching them to specific requirements, enterprises can achieve optimal balance between label quality, production efficiency, and cost control—creating labels that not only convey information but also enhance brand value.