Address

Building C2, Zhanglong Logistics Park

Shiting Sub-district, Xiangcheng District, Zhangzhou City

Fujian Province, P.R. China

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

Building C2, Zhanglong Logistics Park

Shiting Sub-district, Xiangcheng District, Zhangzhou City

Fujian Province, P.R. China

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

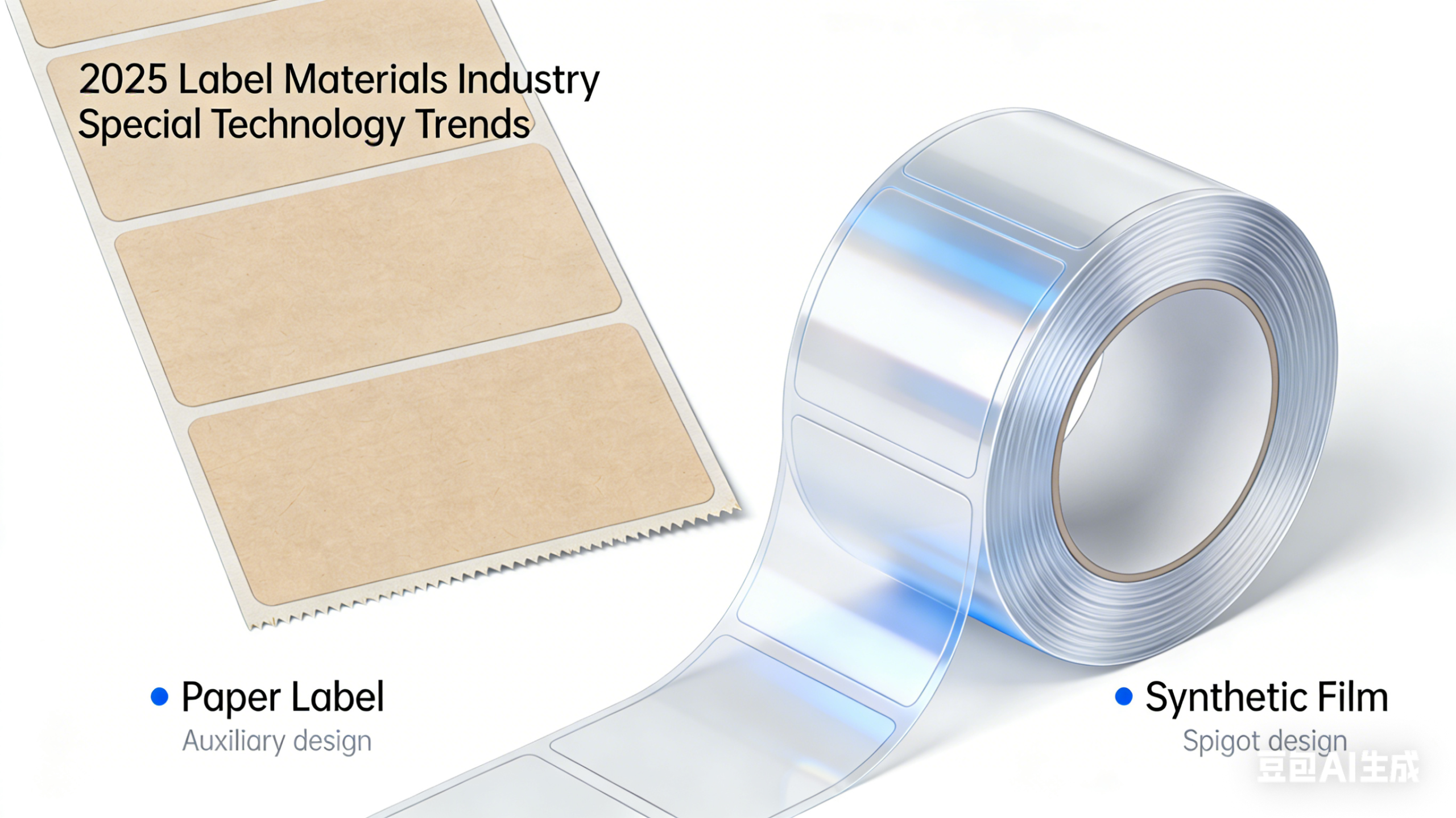

1. Introduction: The Evolving Landscape of Self-adhesive Labels in 2025

The self-adhesive label industry has witnessed remarkable growth driven by expanding application sectors, technological innovations, and escalating demands for sustainability and functionality. As the global market matures, 2025 marks a pivotal year where material selection becomes increasingly critical—linking product protection, brand image, regulatory compliance, and environmental responsibility.

Self-adhesive labels, composed of face material, adhesive, and release liner, have transcended their traditional role as mere information carriers to become integral to product value chains. From food and pharmaceuticals to electronics and logistics, the right material choice directly impacts label performance, consumer perception, and operational efficiency. This guide navigates the spectrum of label materials, from classic paper options to advanced synthetic films, equipping professionals with actionable selection strategies tailored to 2025’s industry trends.

2. Paper-based Self-adhesive Materials: Timeless Options with Targeted Applications

Paper remains a staple in self-adhesive labeling due to its cost-effectiveness, printability, and biodegradability. While overshadowed by synthetic films in harsh environments, 2025 sees renewed interest in paper materials enhanced by eco-friendly treatments and performance upgrades, aligning with global sustainability goals.

2.1 Common Types and Core Characteristics

2.2 2025 Trends for Paper Materials

Sustainability drives innovation in paper-based labels, with manufacturers integrating recycled fibers (up to 80% in premium grades) and water-based adhesives to meet EU and North American environmental standards. Additionally, “functional paper”—treated with water-repellent coatings or UV inhibitors—expands paper’s utility into previously synthetic-dominated sectors like fresh produce labeling <superscript:1>.

3. Synthetic Film Materials: The Engine of High-performance Labeling

Synthetic films dominate the high-growth segments of the 2025 label market, offering superior durability, chemical resistance, and versatility. Derived from polyolefins, polyesters, and other polymers, these materials address the rigorous demands of harsh environments, irregular surfaces, and long-term use—from industrial machinery to outdoor signage.

3.1 Key Types, Properties, and Applications

| Material Type | Core Properties | Temperature Resistance | Typical Applications |

| PE (Polyethylene) | Soft, flexible, waterproof, oil-resistant; excellent for curved surfaces | -20℃ ~ 100℃ | Shampoo bottles, detergent containers, squeeze food packaging <superscript:3> |

| PP (Polypropylene) | Matte or glossy finish, tear-resistant, recyclable; ideal for thermal transfer printing | -20℃ ~ 100℃ | D日化 products, electronic components, outdoor promotional labels <superscript:2> |

| PET (Polyester) | High strength, scratch-resistant, chemical-resistant; available in transparent/metallic finishes | -20℃ ~ 150℃ (up to 280℃ for short-term use) | Electronics (circuit boards), automotive parts, premium cosmetics <superscript:5> |

| PVC (Polyvinyl Chloride) | Flexible, weatherproof, cost-effective; but limited eco-friendliness | -10℃ ~ 60℃ (extended range: -196℃ ~ 280℃ for specialized grades) | Water bottles, electrical panels, battery labels<superscript:5> |

| Synthetic Paper | Combines paper printability with film durability; fully recyclable | -20℃ ~ 120℃ | High-end food packaging, outdoor signage, eco-conscious brands <superscript:3> |

3.2 2025 Innovations in Synthetic Films

Two trends define synthetic film development in 2025: sustainability and multifunctionality. Biodegradable PE/PP blends, made from plant-based polymers, now match traditional films in performance while decomposing within 18 months in industrial compost. Meanwhile, “smart films” integrated with RFID chips or temperature sensors are gaining traction in pharmaceutical cold chains and luxury goods tracking, enabling real-time product monitoring <superscript:1>.

4. Adhesives and Release Liners: The Unsung Heroes of Label Performance

Material selection extends beyond face stock—adhesives and release liners directly influence label application, longevity, and recyclability. 2025’s regulatory focus on low-VOC (volatile organic compound) products drives the shift to eco-friendly adhesive formulations.

Silicone-coated liners remain standard, but 2025 sees growth in recyclable liners (paper-based or silicone-free PE) to reduce waste. For high-precision applications like electronics, ultra-thin PET liners enable better die-cutting accuracy and automated application <superscript:2>.

5. 2025 Label Material Selection Framework

The optimal material choice balances application requirements, regulatory compliance, and cost. Use this step-by-step framework to make data-driven decisions:

5.1 Step 1: Define Application Parameters

5.2 Step 2: Align with Regulatory and Sustainability Goals

5.3 Step 3: Optimize for Printing and Production

Match materials to printing technologies: Digital printing (e.g., inkjet) works best with coated paper or synthetic films with smooth surfaces; thermal transfer printing requires PP or PET for durability <superscript:2>. High-speed production lines benefit from films with consistent thickness to prevent jams.

5.4 Step 4: Balance Cost and Performance

Paper materials cost 30-50% less than synthetic films but may require lamination (adding 10-15% to costs) for moisture resistance. For high-volume applications like beverage labels, PE films offer the best cost-performance ratio; for premium products, metallic PET enhances brand value despite higher costs <superscript:4>.

6. Conclusion: Embracing Flexibility and Innovation in 2025

The 2025 self-adhesive label market demands a nuanced approach to material selection—one that integrates performance, sustainability, and regulatory compliance. Paper materials remain relevant for cost-sensitive, eco-friendly applications, while synthetic films continue to evolve with biodegradable and smart functionalities. By leveraging the framework outlined in this guide, businesses can select materials that not only meet operational needs but also strengthen brand reputation in an increasingly competitive landscape.

As technology advances, partnering with material suppliers to co-develop custom solutions (e.g., brand-specific synthetic papers or smart adhesive systems) will become a key differentiator. The future of labeling lies in materials that work harder—for products, consumers, and the planet.